Need Help Ordering?

Give us a call or see our Selection Tips below!!!

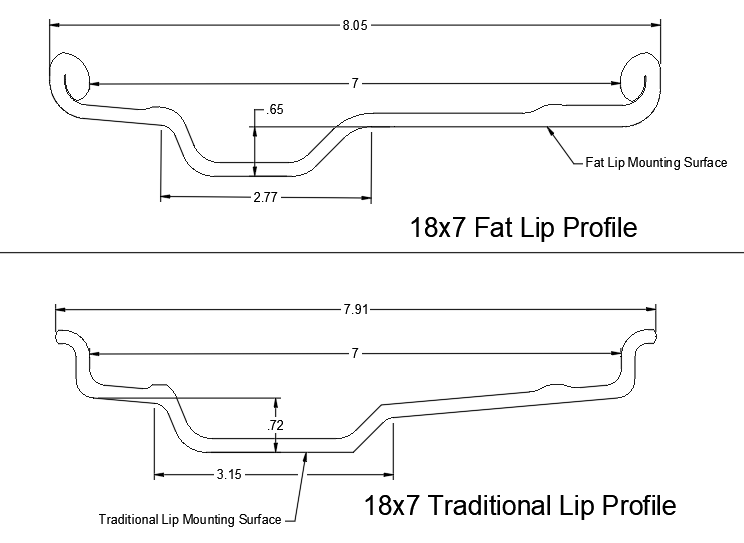

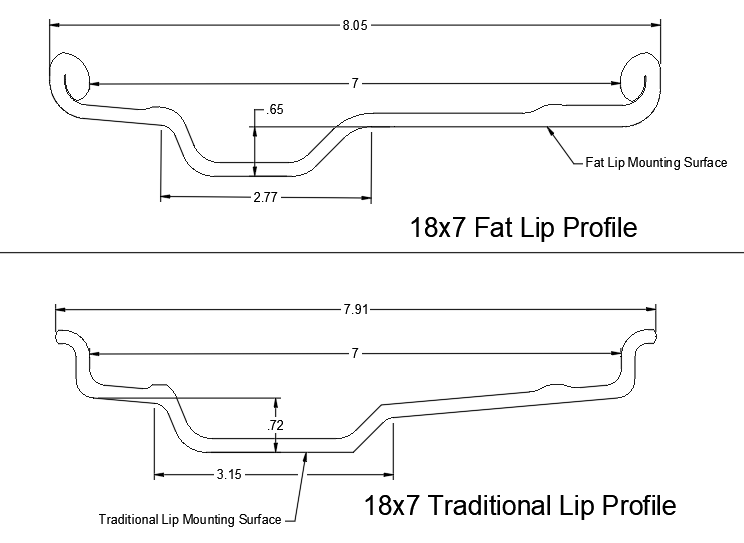

Every aspect of your wheels contributes to their overall appearance, right down to the front lip profile. Typically, there are two main lip profiles on the market.

Fat Lip rims, also known as Deep Dish, Reverse-Lip, or Smooth lip, are our most popular choice. They feature a seamless transition from where the tire ends to where the metal begins, creating a smooth path from the tire to the wheel’s center. This design allows for a larger diameter center, a wider offset range, and the added benefit of extra-strong double-wall beads. The ultra-smooth profile, combined with our Budnik Polish, produces a striking optical illusion, making the wheel appear even deeper than it truly is.

The Traditional Lip rims, often referred to as Step-Lip rims, embody a time-tested standard. Known for their smaller diameter center, wider drop center, and outward-facing valve stems, they offer slightly less range in offset (Backspacing) due to the change in profile. Even so, they continue to be called “Traditional” for a good reason.

See the image below for a comparison between the two profiles.

As shown above, you can clearly distinguish our Fat Lip Profile from the Traditional Lip Profile. For Fat Lip rims, the outward-facing side is on the right, while Traditional Lip rims have their outward side on the left. Here are a few key points about these profiles:

- Total Width

Although both are labeled as 18x7" wheels, their overall width can be as much as an inch larger. This is critical if you’re basing measurements on existing wheels; that extra inch might lead to unexpected fitment issues. The Bead-to-Bead measurement—exactly 7"—is what the “18x7” designation references. - Offset Availability

We’ll explore offset in detail below, but note that you can see where the wheel center and mounting surface align. For additional information, refer to the “Backspace, Frontspace, and Offsets” section. - Valve Stem Placement

On Fat Lip Profiles, the valve stem is behind the wheel center on the drop center, offering a seamless look at the expense of slightly more effort when inflating. Traditional Lip Rims can have the valve stem in the step lip or rear facing, giving you either easy tire filling or a more hidden appearance.

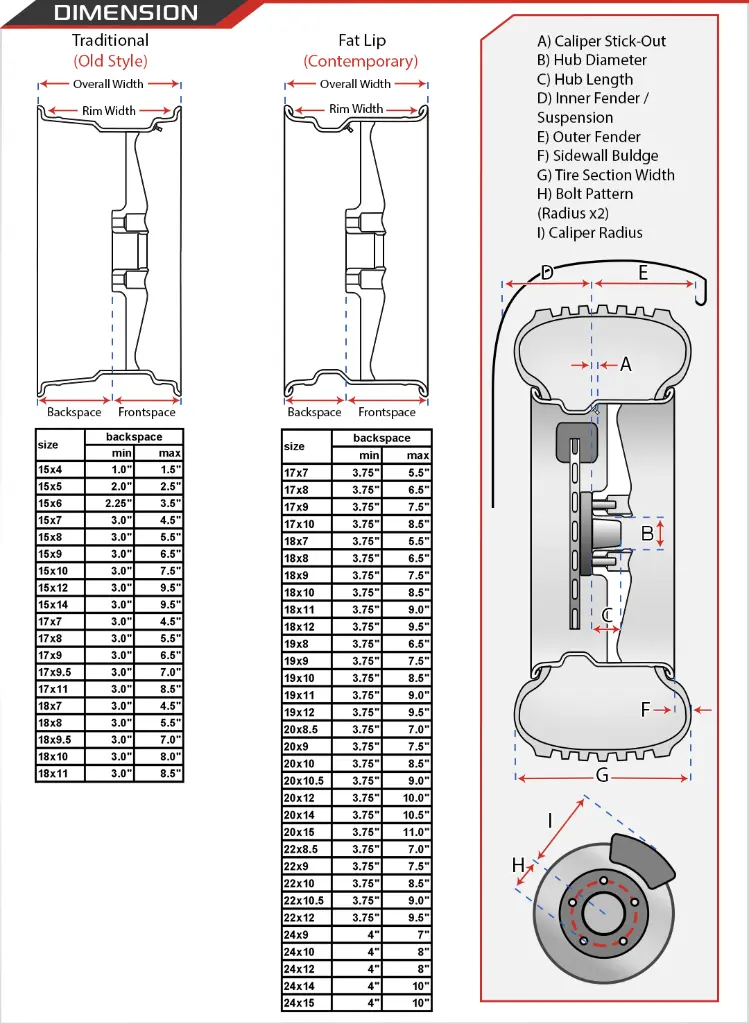

Proper fitment is crucial to ensure the ideal balance between wheel size, sidewall height, and appearance. Our goal is to offer you the right designs and sizes, but be aware that certain limitations may apply—always confirm compatibility before making your choice.

Whether you’re looking for large rear wheels or standard replacements, we provide a range of widths to meet your needs. Keep in mind that the width listed is the “Bead-to-Bead” measurement, not the total wheel width (see the previous section for more details). Below is a table covering all the sizes we offer; however, some sizes are limited to specific wheel series.

Fat Lips:

15" - Not Available

17" x 7"/ 8" / 9" / 10"

18" x 7" / 8" / 9" / 10" / 11" / 12"

19" x 8" / 9" / 10" / 11" / 12"

20" x 8.5" / 9" / 10" / 10.5" / 11" / 12" / 15"

22" x 8.5" / 9" / 10" / 10.5" / 12"

24" x 9" / 10" / 12" / 14" / 15"

Traditional Lips:

15" x 4" / 5" / 6" / 7" / 8" / 9" / 10" / 12" / 14" / 15"

17" x 7" / 8" / 9.5" / 11"

18" x 7" / 8" / 9" / 9.5" / 10" / 11" / 12"

20" x 8" / 9" / 9.5" / 10" / 12"

**We strive to keep our information accurate, but this chart may not always reflect the latest updates. Double check product pages or call us to confirm sizing for your application.**

Selecting the right center cap is one of the most important final steps in customizing your wheels. Our standard lineup features the Standard Smooth Cap, Short Spline-Cap, and Tall-Splined Cap—each offering a distinctive look and function.

- Smooth Caps

Ideal for any build, these caps have a sleek, seamless design that complements your wheels without drawing too much attention. - Short Spline Caps

Perfect for those wanting a more technical appearance, these caps guide the eye toward the wheel’s center. They offer extra dimension when compared to the Smooth Cap, making them a great option for a subtle change. - Tall Spline Caps

An extended version of the Short Spline Cap that provides a strong, standout appearance. These are also beneficial for wheels with long hubs, ensuring both style and practicality.

Big brake kits are a popular upgrade thanks to their performance and visual impact, but they also require extra care when it comes to wheel fitment. In many cases, your caliper will extend beyond the wheel’s mounting surface—this “caliper stick-out” is typically documented in a “wheel clearance diagram” supplied by brake kit manufacturers like Willwood or Baer. This diagram highlights key measurements such as brake diameter, caliper stick-out, and bore details, all of which help ensure proper wheel clearance.

To accommodate these components, the brake clearance pad dimension adds the necessary space behind the wheel for both the caliper and hub. Our go-to recommendation is a 1.1" pad, which generally works for most brakes and hub lengths. Just be sure to maintain at least 0.200" of clearance between the wheel and caliper. Since the rear of our wheels is typically flat (unless otherwise noted), a 1.1" pad provides exactly 1.1" of total clearance. For further guidance on measurements, consult the Backspace and Center Bores sections.

Backspace, our preferred reference, measures the distance from the wheel’s rear face to its mounting surface. You may also hear it referred to as frontspace or offset, depending on which side of the wheel you’re measuring from.

- Frontspace

This is the opposite of backspace—measured from the wheel’s front face back to the mounting surface. When you combine backspace and frontspace, you get the wheel’s overall width. If you’re seeking a specific amount of lip or “dish,” frontspace is the dimension to watch. - Offset

Offset is the distance from the wheel’s centerline to its mounting surface. Although it’s commonly used, calculating offset can require a few extra steps. You’ll need to measure frontspace or backspace, determine the wheel’s total width and divide it by two for the centerline, then subtract accordingly to find the offset.

Because each vehicle, suspension setup, and custom component is unique, we don’t provide universal backspace recommendations. We can offer suggestions based on similar orders, but the best approach is to measure your own setup and decide exactly how you want your wheels to fit.

Hub diameter and length are key considerations when ensuring proper wheel fitment. Our order form accommodates both measurements, although this flexibility might limit some of your design choices.

Bore Diameters / Hub Diameters

Because our wheels are not typically hub centric, you simply need a bore diameter larger than the vehicle’s hub. We recommend 3.072" (78.03 mm), but remember that all measurements are provided in inches—so convert as needed.

Hub Lengths and Related Dimension

Although hub length rarely causes issues, it can be a problem if overlooked. Brake clearance pads, wheel series, and center cap style all influence how much space is available for longer hubs. Our standard 1.1" brake clearance pad also provides an additional 1.1" of hub clearance. Increasing this pad dimension further boosts clearance, and if you need just a bit more space, a tall splined cap can make all the difference.

Bear in mind that G-series and SKO-series wheels offer the least clearance, while X-Series provides the most. A detailed dimension sheet will be released soon, but in the meantime, keep tabs on your hub measurements and contact us for confirmation if you’re unsure about fitment.

Bolt Patterns

Begin by verifying the correct bolt pattern for your vehicle and reconfirm it for each wheel, especially if you’ve made brake or suspension modifications that could alter factory specs.

Lug Nuts

Our wheels are designed to be stud-centric and are drilled to fit standard acorn-style, spline-drive lug nuts (commonly offered by Gorilla Automotive). Select the correct size for your wheel studs, and we’ll include the compatible lug nuts plus a spline-drive socket with your order.

Torque Specs

Properly torquing the lug nuts is critical for both safety and performance. Most standard passenger vehicles use 80-100 ft-lbs. of torque, while light trucks and SUVs often call for 90-120 ft-lbs. However, these figures are only guidelines—the ultimate determining factor is the rating of the studs on your wheel hub. Always consult your vehicle’s manual or the wheel hub/stud manufacturer to confirm the correct torque setting.

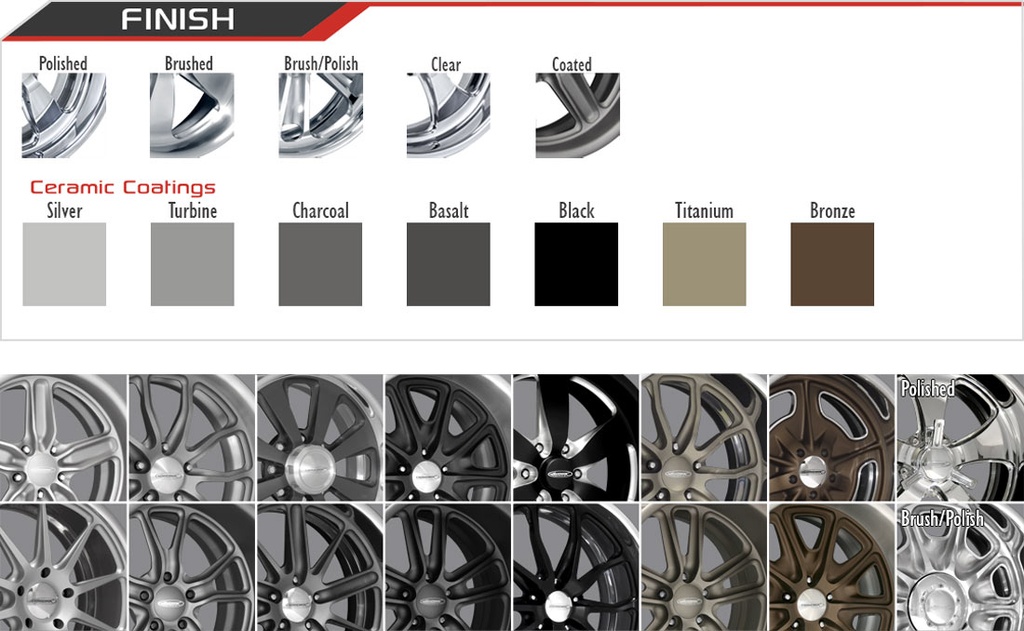

Selecting your wheel’s finish is one of the most exciting parts of the design process. Our standard offering is a dazzling full polish, but if you’re looking for a bit of color or a brushed style, we’ve got you covered. Here’s a quick guide to help you choose:

- Wheel Finish

This is your primary color or coating. Decide on your preferred finish, and then move on to the next step. - Outer Rim Finish

Some of our most popular styles pair polished lips with coated centers. Here, you decide how your rim edges will look. If you select a “Coated Rim,” we’ll use your chosen color from the “Wheel Finish” step. - Center Finish Application

This powerful option lets you apply the chosen finish exactly how you want:- Polished/Brushed/Coated Center: Applies the finish across the entire wheel center.

- Finished Pockets/Face: Targets the recessed “pocket” areas or the top “face” of the wheel for a striking custom appearance. In certain wheel designs, the pattern may differ, so check product images or contact us for more details.

Finally, Center Cap Finishes help tie your caps into the overall design. Whether you want a shiny accent or a seamless match, the choice is entirely yours.

Choosing how the valve stem is positioned can make a big difference in both convenience and style. Our default setup places the valve stem outward, but that can look different depending on the lip profile:

- Traditional Lip

The stem is visibly located along the step lip, making inflation quick and easy. - Fat Lip

Although still facing outward, the valve stem sits behind the wheel center, giving the wheel a cleaner look but requiring you to reach through the center to inflate.

Opting for an inside-facing setup pushes the stem inward toward the suspension. It offers a sleek, uninterrupted face on the wheel but makes inflation harder, which is why many show cars choose this for its flawless appearance.

If you have specific requests, use our special instructions option. We’ll assume standard outward-facing placement if it’s not mentioned. While we strive to meet all custom requests, certain limitations may apply, and if any changes are needed, we’ll contact you to confirm the final details.

The Budnik Split Grip system was built to offer the ultimate flexibility for your steering wheel. Built with the Standard 9-Bolt pattern and an interchangeable grip and numerous customizations we offer a total of 4,698 standard steering wheels. Adding in the option for custom grip colors or wrapping the grip yourself and the variations can be limitless.

We offer our steering wheels in two distinct sizes: A tight and controlled 13.75" diameter, and the broader more classic 15.5" diameter. These sizes may seem close but it really is a world of difference.

As with our road wheels we offer the same protective coatings, shining polish, and brushed aluminum looks our customers have loved for years. See our Budnik Finishes article to learn more.

10 standard grip colors and custom options allowing you to wrap your own or send us a custom material to wrap it for you the choice is yours. Just note to wrap your wheel we use a 20"x20" square to make sure we have enough material to get a good cut and make your wheel perfect.

The perfect steering wheel is often the final touch for a build that helps you connect with the road. We hope that we can provide the perfect fit for your ride.

While the 9-Bolt Pattern is the standard for aftermarket steering wheels, your factory steering column likely does not support it. Which is precisely why we offer a gm column adapter to convert your gm spline to the 9 bolt pattern. Our adapter is designed with smooth elegant curves to make a seamless fit to your vehicle. Our adapters work for GM/Chevy vehicles years 67-94. Should you need a conversion kit for other years or manufacturers, we unfortunately do not manufacture them at this moment. We recommend Lecarra Steering wheel adapters as they provide options for most columns out there.

You changed your steering wheel and probably the hub as well so its likely you will need a horn as well. We offer our standard horn with our oval logo button made out of billet aluminum and built to stand the test of time with matching finish options. Select the option when ordering your steering wheel to either match your ceramic coat, polish, or brushed finish. Or don't! Matching finishes is not uncommon. A coated wheel and polished horn or adapter can have a great look, it is all up to you!!

?unique=5b74d68)

SKO - Series Wheel

Should you have difficulties please don't hesitate to reach out to us at Sales@budnik.com or (714)-892-1932.

All orders come exactly as described through options selected on product page. Please double check to ensure everything is accurate and as desired. If you need assistance please see the "Selection Tips" at the bottom of the page.

Specifically for Road Wheel orders:

Ensure that your cart contains the appropriate number of wheels. For example if you are ordering fronts and rears please build out either fronts or rears and add 2 to your cart. Then build out the other pair of wheels and add those to your cart.

If you are ordering directional wheels, you will need to build out 4 separate wheels to accommodate for each design needed.

While we will double-check your order and confirm any changes necessary, we cannot guarantee the same delivery date if changes or corrections are necessary.

If you need any assistance do not hesitate to contact us!

| Backspace: inches |

Every aspect of your wheels contributes to their overall appearance, right down to the front lip profile. Typically, there are two main lip profiles on the market.

Fat Lip rims, also known as Deep Dish, Reverse-Lip, or Smooth lip, are our most popular choice. They feature a seamless transition from where the tire ends to where the metal begins, creating a smooth path from the tire to the wheel’s center. This design allows for a larger diameter center, a wider offset range, and the added benefit of extra-strong double-wall beads. The ultra-smooth profile, combined with our Budnik Polish, produces a striking optical illusion, making the wheel appear even deeper than it truly is.

The Traditional Lip rims, often referred to as Step-Lip rims, embody a time-tested standard. Known for their smaller diameter center, wider drop center, and outward-facing valve stems, they offer slightly less range in offset (Backspacing) due to the change in profile. Even so, they continue to be called “Traditional” for a good reason.

See the image below for a comparison between the two profiles.

As shown above, you can clearly distinguish our Fat Lip Profile from the Traditional Lip Profile. For Fat Lip rims, the outward-facing side is on the right, while Traditional Lip rims have their outward side on the left. Here are a few key points about these profiles:

- Total Width

Although both are labeled as 18x7" wheels, their overall width can be as much as an inch larger. This is critical if you’re basing measurements on existing wheels; that extra inch might lead to unexpected fitment issues. The Bead-to-Bead measurement—exactly 7"—is what the “18x7” designation references. - Offset Availability

We’ll explore offset in detail below, but note that you can see where the wheel center and mounting surface align. For additional information, refer to the “Backspace, Frontspace, and Offsets” section. - Valve Stem Placement

On Fat Lip Profiles, the valve stem is behind the wheel center on the drop center, offering a seamless look at the expense of slightly more effort when inflating. Traditional Lip Rims can have the valve stem in the step lip or rear facing, giving you either easy tire filling or a more hidden appearance.

Proper fitment is crucial to ensure the ideal balance between wheel size, sidewall height, and appearance. Our goal is to offer you the right designs and sizes, but be aware that certain limitations may apply—always confirm compatibility before making your choice.

Whether you’re looking for large rear wheels or standard replacements, we provide a range of widths to meet your needs. Keep in mind that the width listed is the “Bead-to-Bead” measurement, not the total wheel width (see the previous section for more details). Below is a table covering all the sizes we offer; however, some sizes are limited to specific wheel series.

Fat Lips:

15" - Not Available

17" x 7"/ 8" / 9" / 10"

18" x 7" / 8" / 9" / 10" / 11" / 12"

19" x 8" / 9" / 10" / 11" / 12"

20" x 8.5" / 9" / 10" / 10.5" / 11" / 12" / 15"

22" x 8.5" / 9" / 10" / 10.5" / 12"

24" x 9" / 10" / 12" / 14" / 15"

Traditional Lips:

15" x 4" / 5" / 6" / 7" / 8" / 9" / 10" / 12" / 14" / 15"

17" x 7" / 8" / 9.5" / 11"

18" x 7" / 8" / 9" / 9.5" / 10" / 11" / 12"

20" x 8" / 9" / 9.5" / 10" / 12"

**We strive to keep our information accurate, but this chart may not always reflect the latest updates. Double check product pages or call us to confirm sizing for your application.**

Selecting the right center cap is one of the most important final steps in customizing your wheels. Our standard lineup features the Standard Smooth Cap, Short Spline-Cap, and Tall-Splined Cap—each offering a distinctive look and function.

- Smooth Caps

Ideal for any build, these caps have a sleek, seamless design that complements your wheels without drawing too much attention. - Short Spline Caps

Perfect for those wanting a more technical appearance, these caps guide the eye toward the wheel’s center. They offer extra dimension when compared to the Smooth Cap, making them a great option for a subtle change. - Tall Spline Caps

An extended version of the Short Spline Cap that provides a strong, standout appearance. These are also beneficial for wheels with long hubs, ensuring both style and practicality.

Big brake kits are a popular upgrade thanks to their performance and visual impact, but they also require extra care when it comes to wheel fitment. In many cases, your caliper will extend beyond the wheel’s mounting surface—this “caliper stick-out” is typically documented in a “wheel clearance diagram” supplied by brake kit manufacturers like Willwood or Baer. This diagram highlights key measurements such as brake diameter, caliper stick-out, and bore details, all of which help ensure proper wheel clearance.

To accommodate these components, the brake clearance pad dimension adds the necessary space behind the wheel for both the caliper and hub. Our go-to recommendation is a 1.1" pad, which generally works for most brakes and hub lengths. Just be sure to maintain at least 0.200" of clearance between the wheel and caliper. Since the rear of our wheels is typically flat (unless otherwise noted), a 1.1" pad provides exactly 1.1" of total clearance. For further guidance on measurements, consult the Backspace and Center Bores sections.

Backspace, our preferred reference, measures the distance from the wheel’s rear face to its mounting surface. You may also hear it referred to as frontspace or offset, depending on which side of the wheel you’re measuring from.

- Frontspace

This is the opposite of backspace—measured from the wheel’s front face back to the mounting surface. When you combine backspace and frontspace, you get the wheel’s overall width. If you’re seeking a specific amount of lip or “dish,” frontspace is the dimension to watch. - Offset

Offset is the distance from the wheel’s centerline to its mounting surface. Although it’s commonly used, calculating offset can require a few extra steps. You’ll need to measure frontspace or backspace, determine the wheel’s total width and divide it by two for the centerline, then subtract accordingly to find the offset.

Because each vehicle, suspension setup, and custom component is unique, we don’t provide universal backspace recommendations. We can offer suggestions based on similar orders, but the best approach is to measure your own setup and decide exactly how you want your wheels to fit.

Hub diameter and length are key considerations when ensuring proper wheel fitment. Our order form accommodates both measurements, although this flexibility might limit some of your design choices.

Bore Diameters / Hub Diameters

Because our wheels are not typically hub centric, you simply need a bore diameter larger than the vehicle’s hub. We recommend 3.072" (78.03 mm), but remember that all measurements are provided in inches—so convert as needed.

Hub Lengths and Related Dimension

Although hub length rarely causes issues, it can be a problem if overlooked. Brake clearance pads, wheel series, and center cap style all influence how much space is available for longer hubs. Our standard 1.1" brake clearance pad also provides an additional 1.1" of hub clearance. Increasing this pad dimension further boosts clearance, and if you need just a bit more space, a tall splined cap can make all the difference.

Bear in mind that G-series and SKO-series wheels offer the least clearance, while X-Series provides the most. A detailed dimension sheet will be released soon, but in the meantime, keep tabs on your hub measurements and contact us for confirmation if you’re unsure about fitment.

Bolt Patterns

Begin by verifying the correct bolt pattern for your vehicle and reconfirm it for each wheel, especially if you’ve made brake or suspension modifications that could alter factory specs.

Lug Nuts

Our wheels are designed to be stud-centric and are drilled to fit standard acorn-style, spline-drive lug nuts (commonly offered by Gorilla Automotive). Select the correct size for your wheel studs, and we’ll include the compatible lug nuts plus a spline-drive socket with your order.

Torque Specs

Properly torquing the lug nuts is critical for both safety and performance. Most standard passenger vehicles use 80-100 ft-lbs. of torque, while light trucks and SUVs often call for 90-120 ft-lbs. However, these figures are only guidelines—the ultimate determining factor is the rating of the studs on your wheel hub. Always consult your vehicle’s manual or the wheel hub/stud manufacturer to confirm the correct torque setting.

Selecting your wheel’s finish is one of the most exciting parts of the design process. Our standard offering is a dazzling full polish, but if you’re looking for a bit of color or a brushed style, we’ve got you covered. Here’s a quick guide to help you choose:

- Wheel Finish

This is your primary color or coating. Decide on your preferred finish, and then move on to the next step. - Outer Rim Finish

Some of our most popular styles pair polished lips with coated centers. Here, you decide how your rim edges will look. If you select a “Coated Rim,” we’ll use your chosen color from the “Wheel Finish” step. - Center Finish Application

This powerful option lets you apply the chosen finish exactly how you want:- Polished/Brushed/Coated Center: Applies the finish across the entire wheel center.

- Finished Pockets/Face: Targets the recessed “pocket” areas or the top “face” of the wheel for a striking custom appearance. In certain wheel designs, the pattern may differ, so check product images or contact us for more details.

Finally, Center Cap Finishes help tie your caps into the overall design. Whether you want a shiny accent or a seamless match, the choice is entirely yours.

Choosing how the valve stem is positioned can make a big difference in both convenience and style. Our default setup places the valve stem outward, but that can look different depending on the lip profile:

- Traditional Lip

The stem is visibly located along the step lip, making inflation quick and easy. - Fat Lip

Although still facing outward, the valve stem sits behind the wheel center, giving the wheel a cleaner look but requiring you to reach through the center to inflate.

Opting for an inside-facing setup pushes the stem inward toward the suspension. It offers a sleek, uninterrupted face on the wheel but makes inflation harder, which is why many show cars choose this for its flawless appearance.

If you have specific requests, use our special instructions option. We’ll assume standard outward-facing placement if it’s not mentioned. While we strive to meet all custom requests, certain limitations may apply, and if any changes are needed, we’ll contact you to confirm the final details.

The Budnik Split Grip system was built to offer the ultimate flexibility for your steering wheel. Built with the Standard 9-Bolt pattern and an interchangeable grip and numerous customizations we offer a total of 4,698 standard steering wheels. Adding in the option for custom grip colors or wrapping the grip yourself and the variations can be limitless.

We offer our steering wheels in two distinct sizes: A tight and controlled 13.75" diameter, and the broader more classic 15.5" diameter. These sizes may seem close but it really is a world of difference.

As with our road wheels we offer the same protective coatings, shining polish, and brushed aluminum looks our customers have loved for years. See our Budnik Finishes article to learn more.

10 standard grip colors and custom options allowing you to wrap your own or send us a custom material to wrap it for you the choice is yours. Just note to wrap your wheel we use a 20"x20" square to make sure we have enough material to get a good cut and make your wheel perfect.

The perfect steering wheel is often the final touch for a build that helps you connect with the road. We hope that we can provide the perfect fit for your ride.

While the 9-Bolt Pattern is the standard for aftermarket steering wheels, your factory steering column likely does not support it. Which is precisely why we offer a gm column adapter to convert your gm spline to the 9 bolt pattern. Our adapter is designed with smooth elegant curves to make a seamless fit to your vehicle. Our adapters work for GM/Chevy vehicles years 67-94. Should you need a conversion kit for other years or manufacturers, we unfortunately do not manufacture them at this moment. We recommend Lecarra Steering wheel adapters as they provide options for most columns out there.

You changed your steering wheel and probably the hub as well so its likely you will need a horn as well. We offer our standard horn with our oval logo button made out of billet aluminum and built to stand the test of time with matching finish options. Select the option when ordering your steering wheel to either match your ceramic coat, polish, or brushed finish. Or don't! Matching finishes is not uncommon. A coated wheel and polished horn or adapter can have a great look, it is all up to you!!